Mender attended the Smart Production Solutions exhibition in the NurembergMesse exhibition center on Nov 8-10 last. SPS provides a platform for collaboration between experts in the software development and automation industry. 1,500 exhibitors showcase their expertise to an estimated 65,000 visitors over 3 days.

Mender marketers Karolina Beta and Valeria Ceselli with the “Yocto Jester” Mender Head of Developer Relations Josef Holzmayr on the Mender booth at SPS 2022

Mender had a diverse team in attendance to answer questions from delegates: Valeria Ceselli, Tom Wilke, Karolina Beta and Stephen Cawley joined from the Mender customer engagement team; while Alan Martinovic and Josef Holzmayr attended from the Mender customer engineering team.

We also had a booth presence to educate machine builders and industrial automation providers on how to do edge device management and software management properly.

The edge is getting more intelligent

Device management and software updates are needed for the embedded gateways and controllers on production machines that are used to extract machine data, and also to facilitate remote maintenance. Sensors that track and gather data may also need updating. This is an industry in steady evolution to the so called Industry 4.0 paradigm. Machine data is extracted from production and then it is analyzed to improve productivity and operational efficiency; and to reduce cost and wastage. Both edge and cloud technologies enable this steady evolution. Security and robustness are key strategic concerns as operational technology meets information technology and a new way of operating is created. Increasingly PLCs and HMIs are becoming embedded Linux-based. Where these devices are connected to the cloud, they need encrypted communication tunnels and to be updated with firmware and applications, and secured with vulnerability patching. Where systems on the shop floor are airgapped from the public Internet, they will still need software updating that is encrypted and code signed via USB key or over a local network.

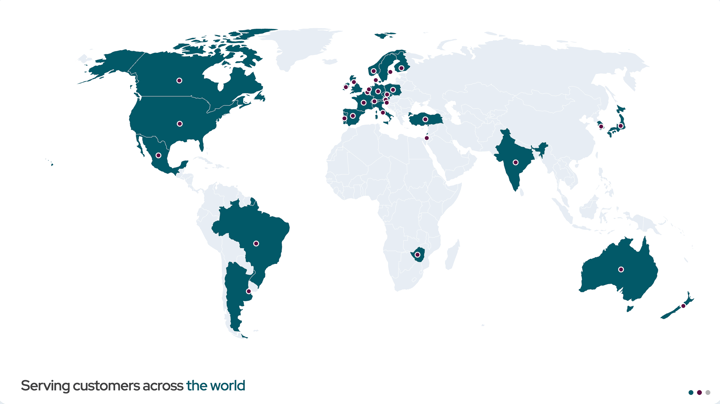

Remote access to, and maintenance of machines, are also services in demand as machine builders look to reduce service costs and improve service to customers who may have factories dotted around the globe.

Mender digital marketing manager Karolina Beta is on hand at the Mender booth to ensure that delegates pick up an OTA software updates checklist

Some SPS exhibition highlights

At the Microsoft Azure booth, the Azure team demonstrated how their Hololens mixed reality headset could be used to visualize a device twin on the factory shop floor.

Mender partner Codestryke explained how they are working with five machine builders to connect their production machines from the shop floor to the Azure cloud, pre-processing the machine data and making it available on the Azure Cloud so that valuable insights can be extracted. Mender provides its over the air software updating and remote device configuration capabilities to Codestryke for use with its VergeLink machine data management solution.

Rockwell Automation was also partnering with Microsoft on the Azure booth and has its own strong presence dedicated to its concept of the Connected Enterprise. Rockwell staff demonstrated how its automation technologies incorporating edge and connected cloud services had been used to help enterprises realize productivity increases of 4-5% per annum, give customers a faster time to market, which included making plants operational in weeks rather than months, quality improvements on the production shop floor which resulted in defects being reduced by up to 50%; and on time delivery increases from 82 to 98%. On a screen at the Microsoft Azure booth, they presented the full end to end infrastructure of the Connected Enterprise Production System in an industry 4.0-enabled factory. It consists of a central hexagon called the Production Data Platform - and addresses the collection and re use of data for 5 distinctive yet interconnected domains:

Analytics, Apps, Access - covers the use of APIs, machine learning, digital twins, low code, the connected worker and dashboards

Machine, Cell, Line, Plant Design - covers the product, process and information requirements so that design and simulation is carried out for critical requirements such as safety, quality, cybersecurity, resiliency, energy and waste management, maintenance and process modelling. These requirements are translated into the critical processes including the control, electrical and mechanical systems, and the human resources and factors that protect employees.

Operations Management - covers the manufacturing execution, asset management, quality management and plant monitoring

Controls, Communication & Compute - covers the need for resilient architecture, communication and security in industrial edge computing, network I/O, 5G, human machine interfaces, and controllers.

Intelligent Devices - covers the mechanical and digital machinery on the shop floor and in the factory infrastructure including drives and controls, sensors, robots, and the systems that control motion, manage power and safety; and enable conveyance and automated handling.

Professional services are needed to ensure optimal design and configuration of these different domains as technology developments move quickly.

Dinner and knowledge sharing with Open Industry 4.0 Alliance Members

The Mender team joined fellow members at the Open Industry 4.0 Alliance SPS dinner and exchanged thoughts on the evolution of Industry 4.0, and how device lifecycle management could be implemented at factories and plants in a way that is open and flexible, while being highly robust and secure. Mender is actively involved in the device management working group in the Alliance. A special thanks to Ekrem Yigitdoel, Managing Director, Open Industry 4.0 Alliance for hosting our team at this dinner.

Enjoying a delicious Indian dinner with fellow Alliance members at the Open Industry 4.0 Alliance SPS Dinner.

The Mender team looks forward to returning to SPS in 2023.

Recent articles

New Mender experimental AI-enabled feature

Mender in 2025: A year in review with compliance, security, and AI-driven growth

What’s new in Mender: Enhanced delta updates and user experience

Learn why leading companies choose Mender

Discover how Mender empowers both you and your customers with secure and reliable over-the-air updates for IoT devices. Focus on your product, and benefit from specialized OTA expertise and best practices.